Tap into Energy You Never Thought You Had!

The Project

Operations and Management identified that the biogas from their anaerobic digester being flared off into the atmosphere represented wasted energy and profits. A study was conducted by Firebridge Inc. to determine the feasibility and best use for harnessing the energy contained in the biogas.

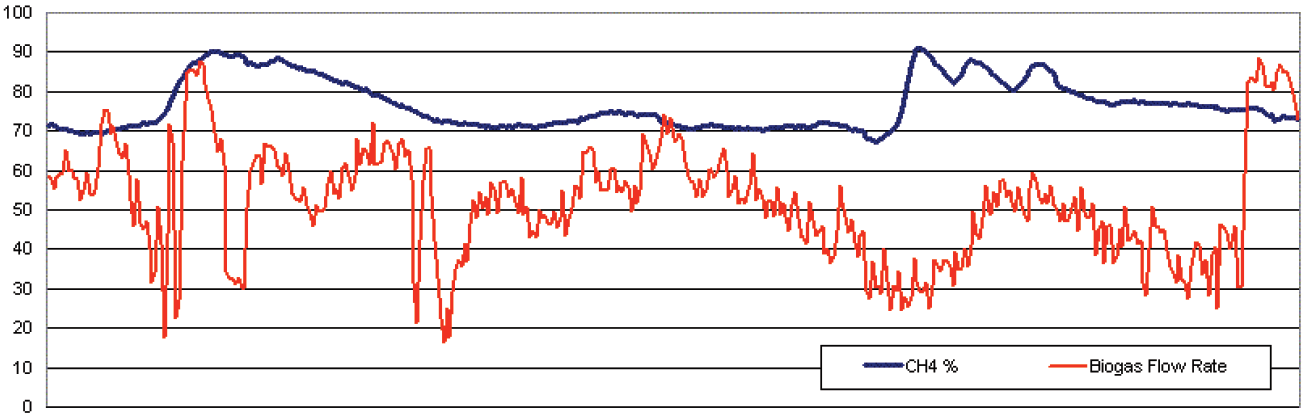

A biogas consumption baseline was developed to benchmark the digester operating efficiencies. This included the analysis of biogas flow rates and chemical compositions. Energy utilization strategies and priorities were determined through a systematic analysis of the existing equipment.

The Firebridge Solution

Using the Six Delta™ Method to gain an optimised perspective, Firebridge identified several performance improvement opportunities. The Six Delta™ Method is a comprehensive approach through a systematic analysis which considers improvements over six interdependent focus areas. This method is data driven by metrics from each focus area which combine to drive a strong business case.

The Six Delta™ focus areas for this project are:

Primary: Energy Consumption – Product Quality – Process Production – GHGe Emissions

Secondary: Safety & Compliance – Equipment Reliability

Firebridge was able to provide several options and system solutions for the use of the biogas as a fuel. By recuperating the biogas the customer was able to offset natural gas consumption and find significant cost savings.

Biogas Quantity and Quality Profile

Time [Over 1 Week Period]

“Investing in a study will give you the clarity and decision making tools to save hundreds of thousands of dollars in annual energy!”

– Russ Chapman, President, Firebridge Inc., 2019

![]()

Improved results were found across all Six Delta™ focus areas.

Safety & Compliance

- Identified process safety improvement through elimination of biogas burn off

Quality

- Quality of gas and analysis of chemical impurities identified applications for biogas as a fuel

Productivity

- Annual fuel savings of $225,000

- Payback period of 1.8 years

Energy Consumption

- 2.5 MMBTU/hr of usable heat was available

Reliability

- Possible use in boiler applications to generate high quality steam

- Possible use as a fuel in electric generation/co-generation

Greenhouse Gas Emissions

- Ability to eliminate all biogas from being flared and displacing the natural gas thus reducing green house gas emissions

Liked what you read? Stay up to date with new content by Subscribing below!